Wholesale Sullair Replacement Parts 2250049-889 2250078-031 Air Compressor Oil Separator

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

Screw air compressor Shouli oil and gas separation filter (part No. 2250049-889) is the core component of screw air compressor oil and gas separation system, mainly used to separate the oil and gas mixture in the compressed air, to ensure the cleanliness of the output gas and reduce the energy consumption of equipment operation. The filter element is specially designed for Shouli series air compressor, suitable for specific models, need to be combined with the equipment technical manual to confirm the compatibility.

From the perspective of structure, the filter element adopts multi-layer composite filter material, the outer layer is high-precision glass fiber, the inner layer is oleophobic polyester fiber, and the gas liquid is efficiently separated by gradient filtration design. The filter material has been specially oleophobic treatment, which can reduce the adhesion of oil molecules and extend the service life. The frame adopts galvanized steel mesh support structure to ensure the structural stability under the working pressure of 0.3-1.3MPa. The axial sealing ring is made of fluorine rubber material, which can withstand high temperature up to 120℃ and has good sealing performance.

In terms of technical parameters, the filtration accuracy is less than 0.1μm, the initial pressure difference is less than 0.2bar, and the maximum allowable pressure difference is 1.0bar (to be monitored with a pressure difference sensor). It is recommended to replace when the pressure difference exceeds 0.7bar or after 4000-6000 hours of operation. The product complies with the ISO 8773-1 air quality standard, and the oil content of the gas after treatment is less than 3ppm (under normal working conditions), which can effectively protect the back-end gas equipment.

During maintenance, the installation direction should be consistent with the air flow mark to prevent the filter material from being compressed and deformed. The storage environment should be kept dry to avoid aging of seals caused by direct ultraviolet rays. The failure of the filter element is mainly manifested as the increase of exhaust oil content, the increase of equipment power consumption and the abnormal increase of oil temperature, which needs to be monitored with the oil partial pressure difference meter. It is suitable for fixed air compressor system in manufacturing, mining, power generation and other fields.

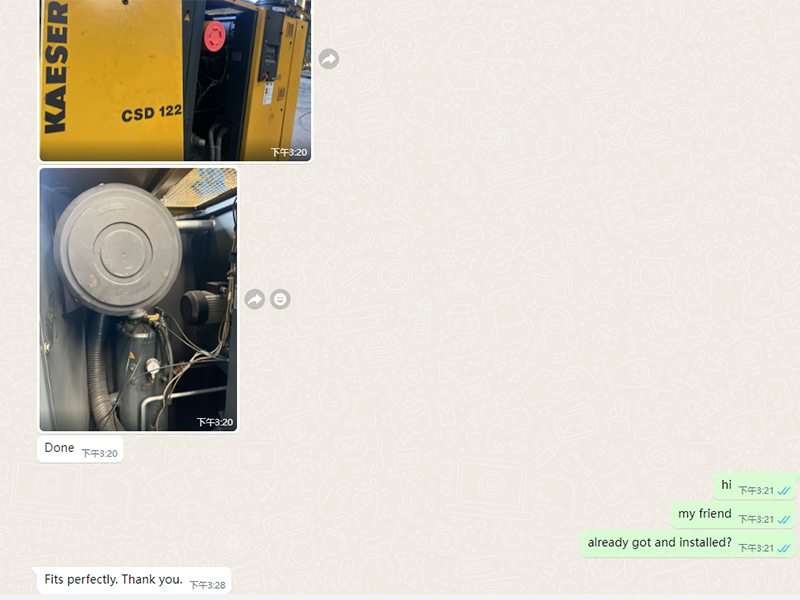

Customer Feedback

.jpg)

Buyer evaluation