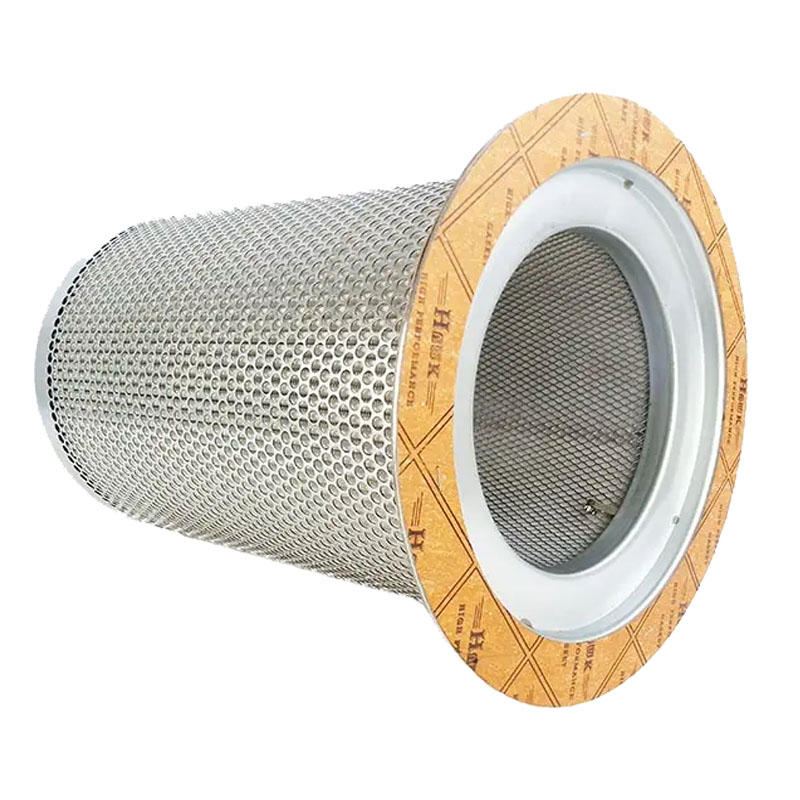

Wholesale Screw Air Compressor Parts Spin-on Filter System 6221372500 6221372800 Oil Separator

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

Oil and gas separator filter is a kind of equipment designed to meet the needs of separating oil from gas in oil and gas collection, transportation and other industrial processes. It can separate the oil from the gas, purify the gas, and protect downstream equipment. Oil and gas separators mainly rely on gravity separation to achieve the work, according to the different structures of oil and gas separators, can be divided into gravity oil and gas separators and swirl oil and gas separators.

Gravity oil and gas separator uses the density difference of oil and gas to leave liquid in the separator, and the gas is discharged through the outlet at the top of the separator. The swirling oil and gas separator separates the oil and gas in the separator through the action of eddy current. No matter what kind of separator, it is necessary to rely on its internal structure to increase the effect of separation.

Separation process steps of oil and gas separator filter:

1. The oil and gas mixture enters the separator: The oil and gas mixture enters the inlet of the separator through the pipeline, and the mixture does not separate at this time.

2. The oil and gas mixture is blocked in the separator: After the oil and gas mixture enters the separator, the speed will be slowed down because of the structure. In this process, the oil and gas begin to separate due to the different density.

3. Oil flows to the bottom of the separator: Because the density of oil is greater than the gas, the oil will naturally precipitate to the bottom of the separator at this time. The bottom of the separator is called the separation chamber, and its role is to receive the precipitated liquid.

4. Air flow to the top of the separator: the gas will rise to the top of the separator, and after the removal of liquid droplets and other processes, discharge the outlet at the top of the separator.

5. Oil into the oil pipe: the oil in the separation room passes through the discharge device and enters the corresponding oil pipe; The gas enters the trachea.