Wholesale Screw Air Compressor Parts Air Filter Cartridge1613950100 54672530 for replace Ingersoll Rand

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

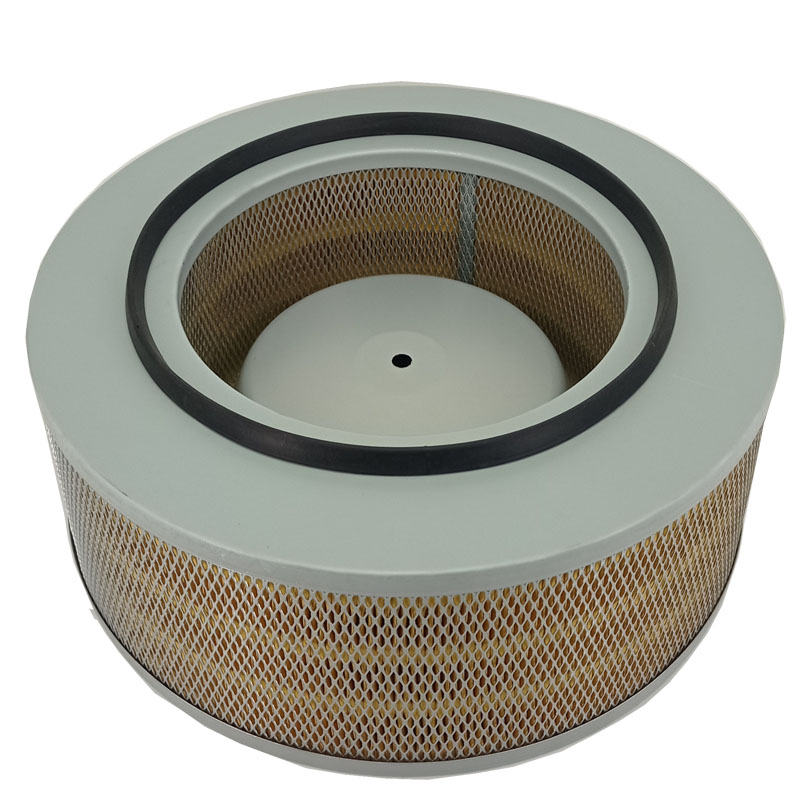

The position of the air filter of the screw air compressor is at the air intake. This design helps to ensure the quality of the compressed air while extending the service life of the air compressor. The installation and use of air filters can choose the right air filter according to the size of the air compressor model and the intake air volume to ensure the best filtration effect.

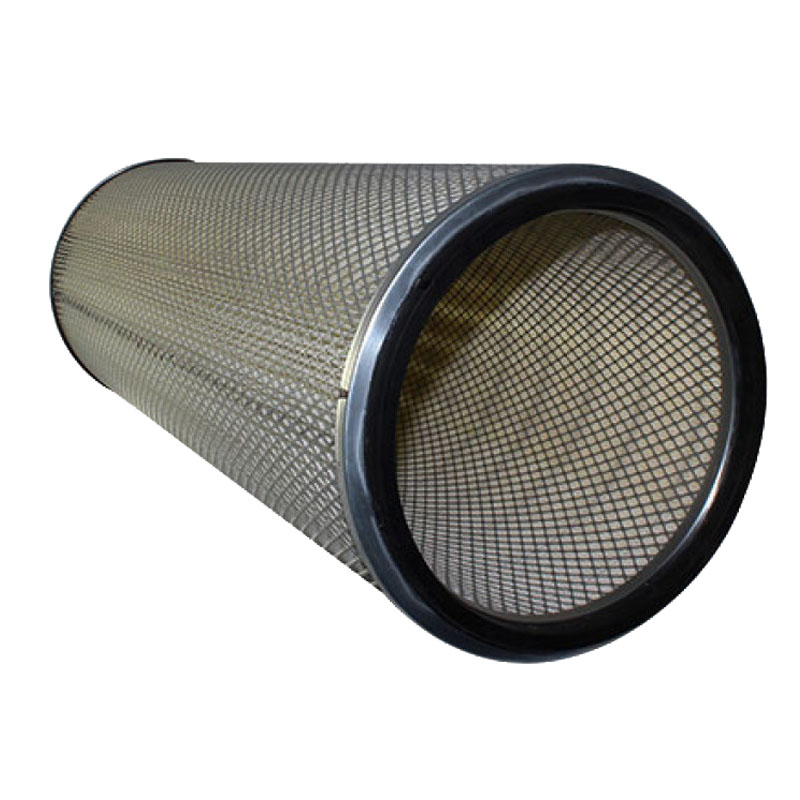

The design of the air filter includes parts such as the air filter shell and the main filter element, in which the air filter shell plays a pre-filtration role, and the large particle dust is pre-separated by rotating classification. The main filter element is the core part of the air filter, which determines the filtration accuracy and service life of the air filter. The combination of these components can not only filter impurities in the air, but also play a noise reduction role to reduce the noise of the air compressor inlet.

The material of air filter core of air compressor mainly includes wood pulp filter paper from HV Company of the United States and Ahlstrom Company of South Korea.

The choice of this filter paper is because it can effectively filter out impurities such as dust, sand, water, oil mist suspended in the ambient air to ensure the purity of the compressed air. Wood pulp filter paper has good filtration performance and long service life, which can usually reach about 2000 hours. In order to maintain the best performance of the filter element, it should be placed in a dry and ventilated place during use to avoid moisture affecting its service life .

In addition, the design of the filter element also takes into account the special requirements of the customer, the vertical air filter design is composed of four basic housings and various filter joints, and does not contain metal parts to ensure safe use. This design ADAPTS to the rated flow rate of different module systems, ranging from 0.8m3/min to 5.0 m3/min, to meet the needs of various application scenarios.