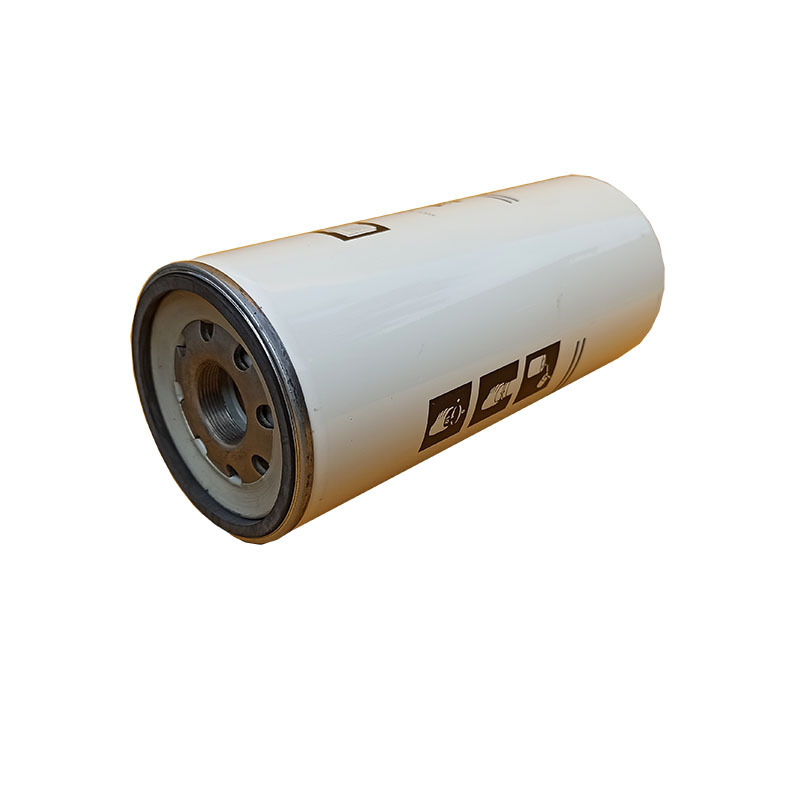

Wholesale Replace 1613800701 1613800700 Atlas Copco Oil Separator Filter

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it. We reply your message within 24 hours.

Oil separator technical parameters:

1. The filtration precision is 0.1μm

2. The oil content of compressed air is less than 3ppm

3. Filtration efficiency 99.999%

4. The service life can reach 3500-5200h

5. Initial differential pressure: =<0.02Mpa

6. The filter material is made of glass fiber from J.C.Binzer Company of Germany and Lydall Company of the United States.

Precautions when installing the oil and gas separator filter element:

1. Apply a small amount of lubricating oil on the surface of the seal when installing the oil and gas separator filter element.

2. During installation, the filter element of the rotary oil and gas separator only needs to be tightened clockwise by hand.

3. When installing the built-in oil and gas separator filter element, a conductive plate or graphite gasket must be installed on the flange gasket of the oil and gas separator filter element.

4. When installing the built-in oil and gas separator filter element, pay attention to whether the return pipe extends to the center bottom of the oil and gas separator filter element between 2-3mm.

5. When unloading the filter element of the oil and gas separator, pay attention to whether there is still excess pressure inside.

6. The compressed air containing oil cannot be directly injected into the filter element of the oil and gas separator.