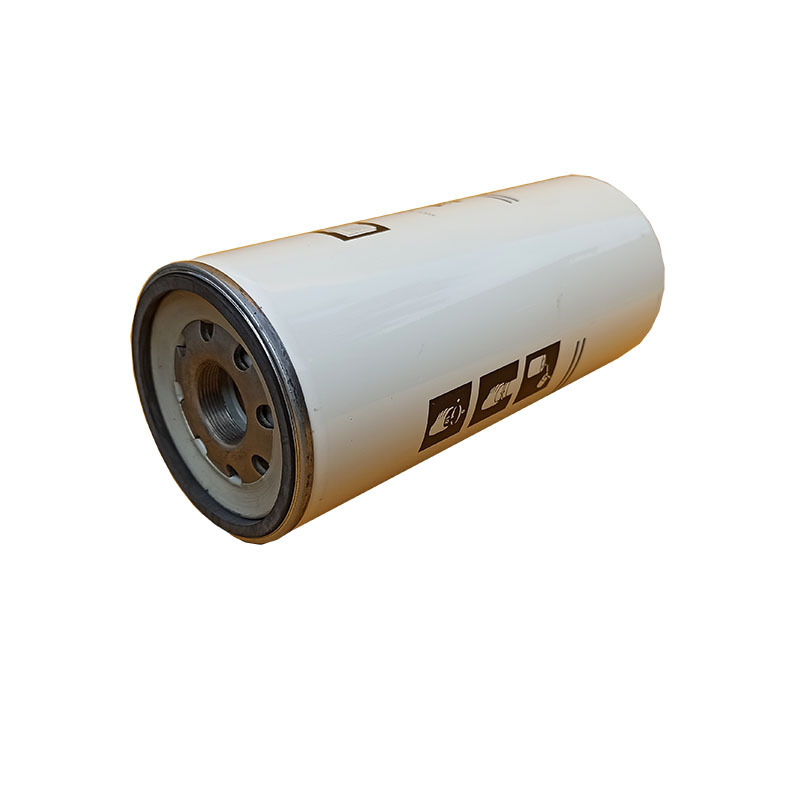

Wholesale Industrial Filter Oil and Gas Separator Filter 2204213899 for Air Compressor Parts Filter

Product Display

Product Description

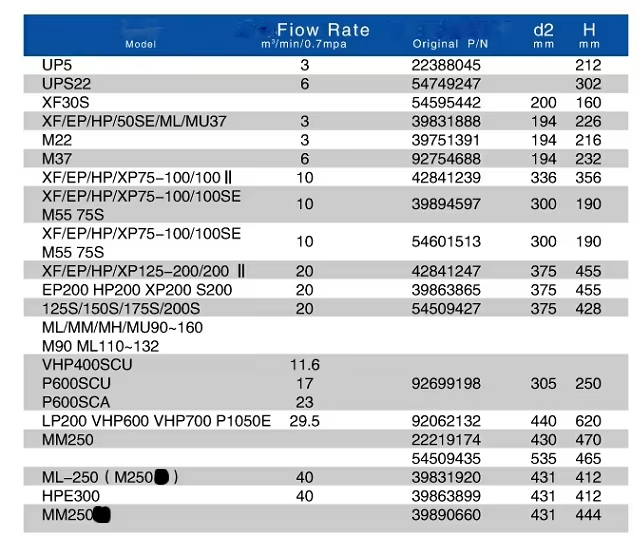

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

Working principle of air compressor oil and gas separation filter element:

There are two common types of air compressor oil and gas separation filter elements, which are built-in oil and gas separator and external oil and gas separator. When the gas entering the separator from the outlet of the air compressor flows through the interior of the separator, due to the slowing down of the flow speed and the change of direction, the lubricating oil and impurities in the gas lose their suspension state and begin to settle. The special structure and design inside the separator can effectively collect and separate these settled lubricants and impurities, and clean gases continue to flow out of the separator to be used by subsequent processes or equipment.

Main components:

- separator cylinder: air compressor oil and gas separator usually adopts cylinder shape design, internal through special structure and structure to promote oil and gas separation. The cylinder is usually made of corrosion-resistant metal materials, such as stainless steel

- air inlet: the air inlet of the air compressor oil and gas separator is connected to the outlet of the air compressor, and the gas containing lubricating oil and impurities is introduced into the separator.

- Air outlet: Clean gas flows out of the separator through the air outlet and is supplied to the subsequent process or equipment.

- Separator filter element: Separator filter element is located inside the separator to collect and separate lubricating oil and impurities. The filter element is usually made of highly efficient filter material glass fiber, which can prevent the passage of lubricating oil particles and impurities.

- Oil drain port: The bottom of the separator is usually provided with an oil drain port for discharging the accumulated lubricating oil in the separator. This can maintain the efficiency of the separator and extend the service life of the filter.

Working process:

- gas into the separator: the gas containing lubricating oil and impurities through the air inlet into the air compressor oil and gas separator.

- sedimentation and separation: the gas slows down and changes direction inside the separator, so that the lubricating oil and impurities begin to settle. The special structure inside the separator and the function of the separator filter help to collect and separate these settling materials.

- Clean gas outlet: After settlement and separation treatment, clean gas flows out of the separator through the outlet and is supplied to the subsequent process or equipment.

- oil discharge: the oil discharge port at the bottom of the separator is used to regularly discharge the accumulated lubricating oil in the separator. This step can maintain the efficiency of the separator and extend the service life of the filter element