Wholesale Air Compressor 1614727300 Coolant Oil Filter Cartridge Products

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

The screw air compressor oil filter is generally set for 2000 hours. The oil core and oil filter should be replaced after 500 hours of the first operation of the new machine, and then every 2000 hours of operation.

Factors that affect the setting time of screw air compressor oil filter include:

Operating environment : In harsh environments, such as dusty or wet environments, the maintenance cycle may need to be shortened, because these environmental factors will accelerate the wear and pollution of the equipment.

Frequency and working load : The maintenance cycle of air compressors with higher frequency of use or larger working load should also be shortened accordingly.

Equipment model and manufacturer's suggestion : screw air compressors produced by different manufacturers may differ in design and quality, so manufacturers will provide recommendations on maintenance cycles according to the specific conditions of the equipment.

Oil quality : high quality lubricating oil can provide better lubrication and protection performance, extend the oil change cycle.

Comprehensive maintenance : In addition to basic maintenance, screw air compressors also require regular comprehensive mechanical and electrical system inspections, which are usually recommended every six months or every year.

The main function of the oil filter in the air compressor system is to filter out metal particles and impurities in the lubricating oil of the air compressor, so as to ensure the cleanliness of the oil circulation system and the normal operation of the equipment. If the oil filter fails, it will inevitably affect the use of the equipment.

Hazards of air compressor oil filter overtime use:

1 Insufficient oil return after blockage leads to high exhaust temperature, shortening the service life of oil and oil separation core;

2 Insufficient oil return after blockage leads to insufficient lubrication of the main engine, which will shorten the service life of the main engine;

3 After the filter element is damaged, the unfiltered oil containing a large amount of metal particles and impurities enters the main engine, causing serious damage to the main engine.

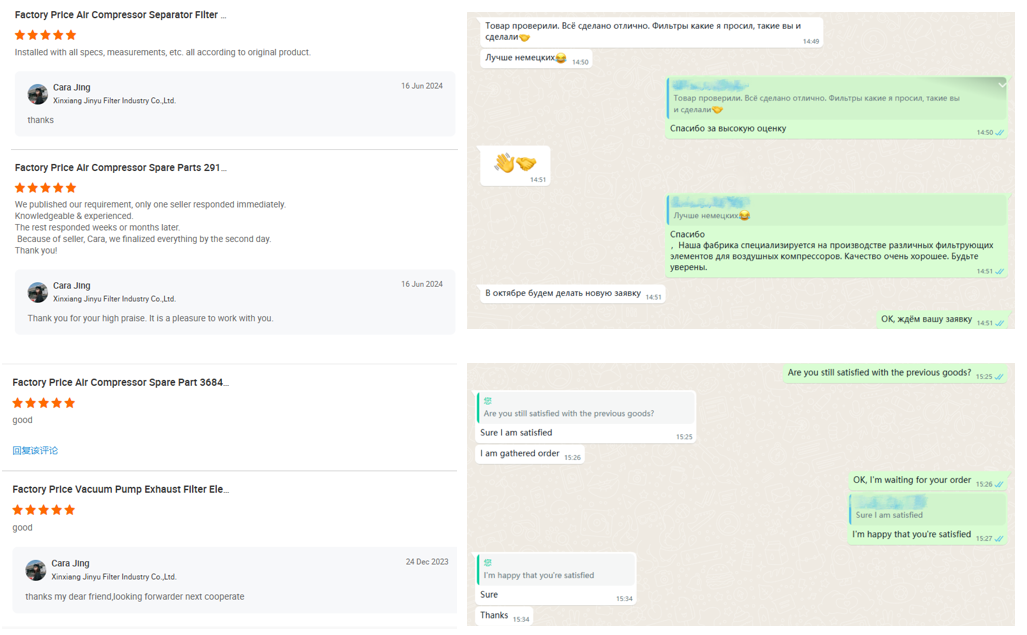

Buyer evaluation