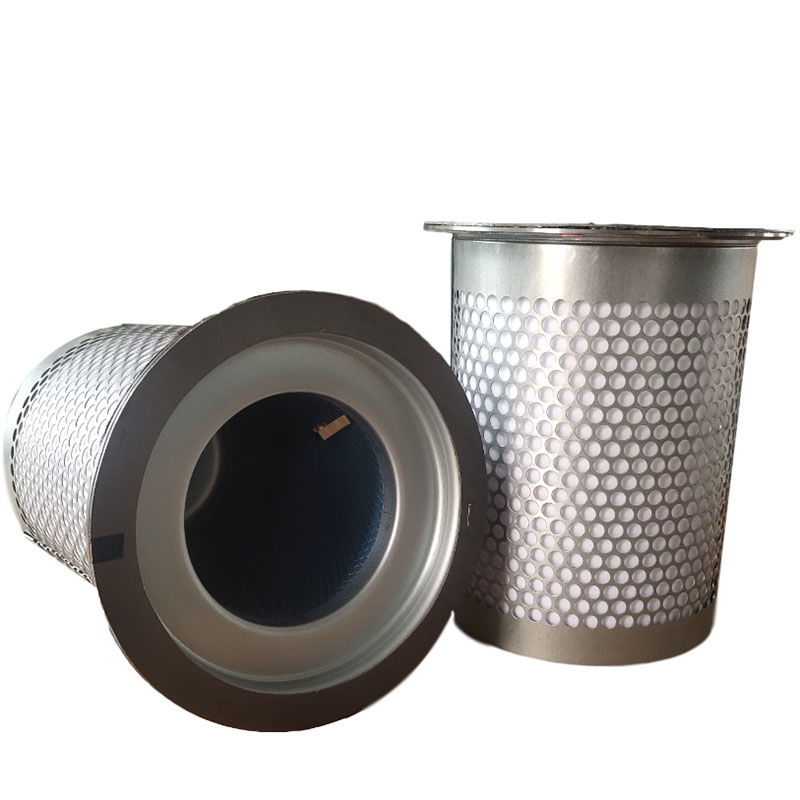

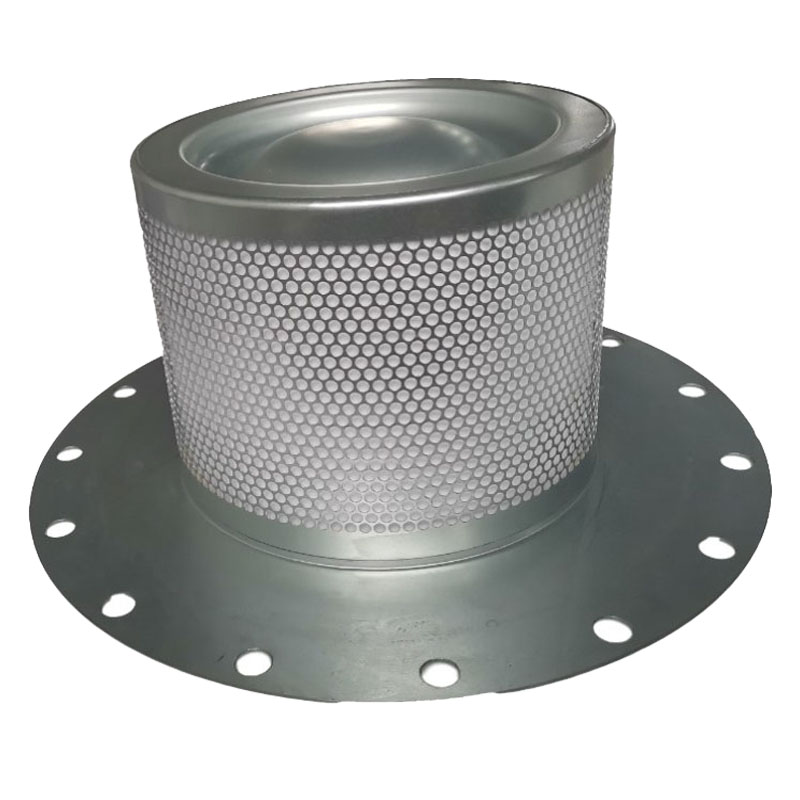

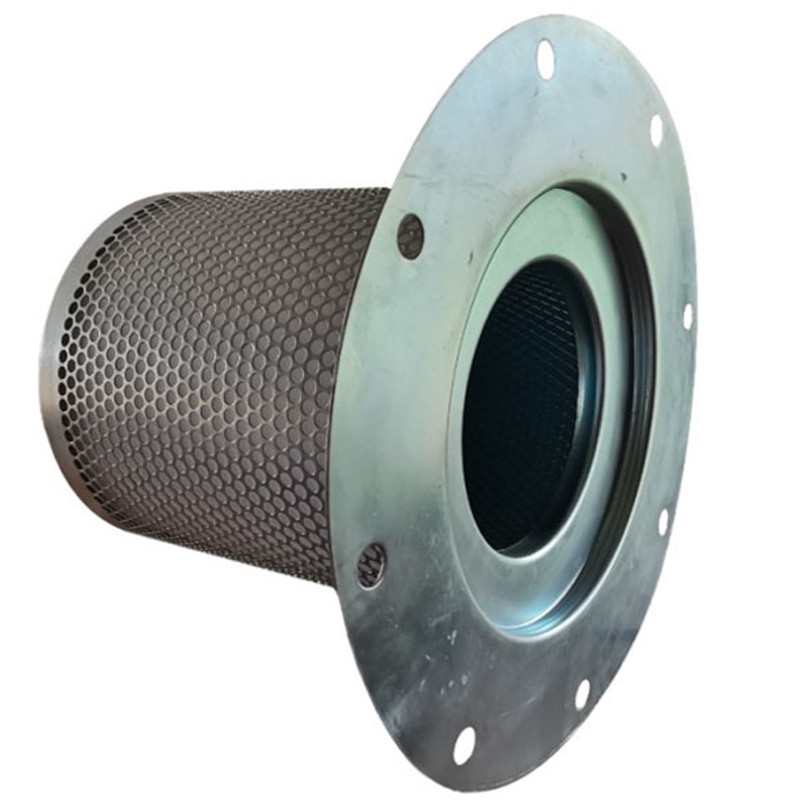

Wholesale Air Compressor Separator Filter 23708423 Oil Separator for Replace Ingersoll Rand

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

The use of air compressor oil and gas separator filter element needs attention:

1. The pressure difference of oil and gas separator filter element is too large

In the process of using the oil and gas separator filter element, the normal pressure difference of the newly installed oil and gas separator filter element for the first time is 0.17-0.3bar, if it is abnormal beyond 0.3bar, it is necessary to check whether the minimum pressure valve of the air compressor or other parts of the air system are damaged. In the process of using the oil and gas separator filter element, the air compressor is constantly using the inhaled air, and many dust particles less than 5um enter the subdivision of the oil and gas separator filter element, which not only makes the processing flow of the subdivision layer continue to decline, but also the pressure difference of the oil and gas separator filter element continues to increase. When the oil and gas separator filter reaches a pressure difference of 1bar in normal use, it is necessary to replace the oil and gas separator filter.

2. The oil content of the oil separator core is too large (>10ppm)

During the use of the oil and gas separator filter, the ideal oil content of the compressed air after the separation of the compressed air containing liquid oil by the oil and gas separator filter is within 3ppm. Before using the oil and gas separator filter, it is necessary to understand whether the volume flow of the air compressor matches the processing flow of the oil and gas separator core, and the configuration of the oil and gas separator core must be greater than or equal to the output flow of the air compressor. In the same type of oil and gas separator filter used in different brands of air compressors, the treatment oil content of the oil and gas separator filter is different.

In the process of using the oil and gas separator filter element, the content of compressed air is more than 10ppm/ (m3min), it is necessary to pay more attention to the amount of oil in the oil and gas barrel and the oil temperature of the air compressor, if necessary, the air compressor is shut down to check whether the return pipe of the air compressor is blocked. The relevant components are checked for damage to the seals and whether the amount of oil in the oil drum is in a reasonable position.

3. Oil and gas separator filter element burning or explosion (smoke. Burnt taste)

In the process of using the oil and gas separator filter, there will occasionally be combustion or explosion in the oil and gas barrel, which is not caused by the oil and gas separator filter. Because the oil and gas separator filter itself is not spontaneous fire, only the ignition and combustion gas two factors exist at the same time will burn and explode, and some oil and gas separator filter friction through the flow rate of gas will produce static electricity, the greater the risk of static electricity. Therefore, the manufacturer of oil and gas separator filter element will install a conductive sheet. Unless there is no reinforced electrostatic sheet on the flange gasket of the oil and gas separator core to conduct electricity during installation, the static electricity generated cannot be dispersed. In the process of using the filter element of the oil and gas separator, it is necessary to prevent the fire and combustion in the oil and gas barrel. Firstly, the conductive sheet is reinforced on the flange gasket of the filter element of the oil and gas separator, and the performance of the gasification amount of the compressor lubricating oil used should meet international standards. Secondly, before installing the oil and gas separator filter, the impurities of the two systems and the welding slag on the weld must be clean, especially the welding slag on the weld of the new machine must be clean. Because the air compressor will produce high temperature and high pressure in operation, and the high-speed gas flow is easy to remove the clean welding slag and produce sparks by colliding with metal parts. Again, it is necessary to often pay attention to whether the noise emitted by the air compressor is normal in operation, and prevent the metal fruit particles generated by the wear of the moving parts of the air compressor from colliding with the metal parts.