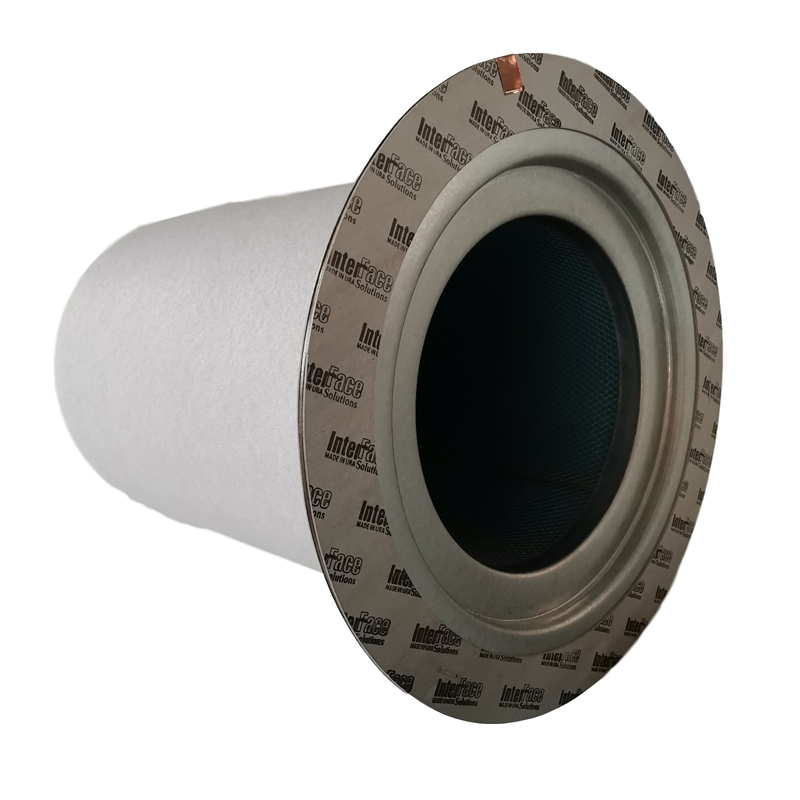

Wholesale Air Compressor Oil Separator Filter Manufacturers 6.3789.0

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

Screw air compressor the main function of the oil-gas separator

The main function of the oil-gas separator of the screw air compressor is to ensure the purity of the compressed air. It ensures that the compressed air output of screw air compressor reaches high purity and oil-free state through the preliminary separation of oil and gas barrel and the secondary fine separation of oil and gas separator.

The specific working principle of oil and gas separator of screw air compressor

The oil and gas separation process of screw air compressor is mainly completed by the initial separation of oil and gas drum and the second fine separation of oil and gas separator. When the oil and gas mixture discharged from the main engine of the screw air compressor enters the oil and gas barrel, most of the oil is deposited to the bottom of the barrel under the dual influence of centrifugal action and gravity. The compressed air containing a small oil mist (suspended oil particles less than 1 micron in diameter) is then passed through the oil and gas separation filter, which is filtered twice using a filter layer of micron and glass fiber filter material. When the oil particles are diffused in the filter material, they will be directly intercepted or gathered into larger oil droplets through inertial collision, and finally collect to the bottom of the oil core under the action of gravity, and return to the main engine lubricating oil system through the bottom return pipe.

The core role of oil and gas separator of screw air compressor

The core role of the oil and gas separator of the screw air compressor is to ensure that the compressed air output of the screw air compressor reaches a high purity and oil-free state through the initial separation of the oil and gas barrel and the secondary fine separation of the oil and gas separator. A high-quality oil and gas separator can not only provide clean and oil-free compressed air, but also ensure the efficient and stable operation of screw air compressors.