Wholesale 731468 0000 Vacuum Pump Exhaust Oil Mist Separator Filter

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

The core breakthrough of 731468-0000 lies in its perflurane rubber (FFKM) sealing system , which can withstand the strong acid and alkali environment of pH 1-14, and its life is 3 times longer than that of conventional fluororubber (FKM). The internal flow channel of the pump body is coated with PTFE coating process to avoid direct contact with corrosive gases of metal parts. At the same time, it is integrated with ceramic coating rotating sheet to maintain the ultimate vacuum stability of 0.3 mbar in the medium containing particles. Its "double cycle" oil circuit design (main cycle lubrication + secondary cycle purification) can actively adsorb acid gas residue and extend the service life of the oil to 4000 hours (1.5 times of the conventional model).

Chemical industry : For chlorine gas, hydrogen sulfide and other gases, built-in chemisorbed filter (activated carbon or molecular sieve module can be optional), exhaust gas emissions meet EPA Tier IV standards.

Electronic industry : In order to avoid backflow leakage, very toxic gases such as NF₃and ClF₃ in semiconductor etching process should be through the vacuum tube negative pressure interlock system .

In the field of new energy : for the EC/DMC solvent vapor of lithium battery injection, the low temperature condensation recovery module is developed. The solvent recovery rate is over 85%, reducing VOCs emissions.

This model is equipped with corrosion rate sensor , which monitors the pH and humidity inside the pump chamber in real time, predicts the aging trend of the seal by AI algorithm, and automatically adjusts the oil temperature (±2°C accuracy) to neutralize the acid residue. Users can view 3D disassembly instructions through AR O&M assistant (start by scanning code on mobile phone). Key parts can be replaced within 10 minutes, with 60% higher maintenance efficiency than traditional maintenance. Reduce waste oil disposal costs by 70% with closed loop oil recycling system (compatible with third-party recycling services) 90% of the structural parts of the machine are made of recyclable stainless steel and engineering plastics, which comply with the European Union's Sustainable Product Ecological Design Regulation (ESPERT). In a typical chemical plant, 731468-0000 has an energy efficiency ratio (COP) of 4.2, which can reduce 12 tons of CO₂equivalent emissions per year, equivalent to the carbon sink capacity of 5 acres of forest.

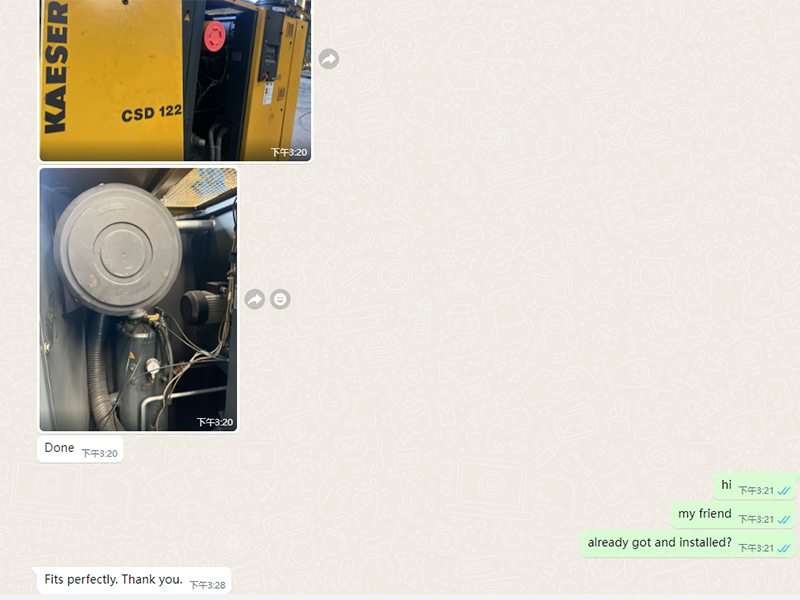

Customer Feedback

.jpg)

Buyer evaluation