Wholesale 6.2013.0 Air Compressor Oil Separator Filter Compressor Factory Manufacturers

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

The replacement cycle of the oil core of the screw air compressor is usually every 3000 to 5000 hours. The specific replacement time depends on a variety of factors, including equipment model, operating environment, operating load, and so on.

Factors affecting the replacement cycle

1. Equipment model and use environment : different brands and models of screw air compressors may have different maintenance requirements. The operating environment has a significant impact on the service life of the oil and gas separator, dusty, high humidity or high temperature environment will shorten the replacement cycle, and clean, dry and suitable temperature environment will extend its service life.

2. Running status : Users should pay close attention to the running status of the device. When it is found that fuel consumption increases, the exhaust oil content exceeds the standard, the oil partial pressure difference is too large, or the indicator lamp alarms, it may be a signal that the oil and gas separator needs to be replaced, and it should be stopped in time to check and replace.

Replacement steps :

1. Stop the machine and confirm that the pressure has been released. Pull down the main power switch.

2. Remove the pipe connecting the small pressure valve.

3. Remove the tubing and other control tubes.

4. Remove the cover of the oil and gas separation tank.

5. Remove the oil and gas separation core and replace it with a new oil and gas separation core.

Precautions :

1. When installing the extraction pipe, it must be ensured that the pipe is inserted into the bottom of the oil and gas separation core to ensure that the residual oil at the bottom is completely extracted.

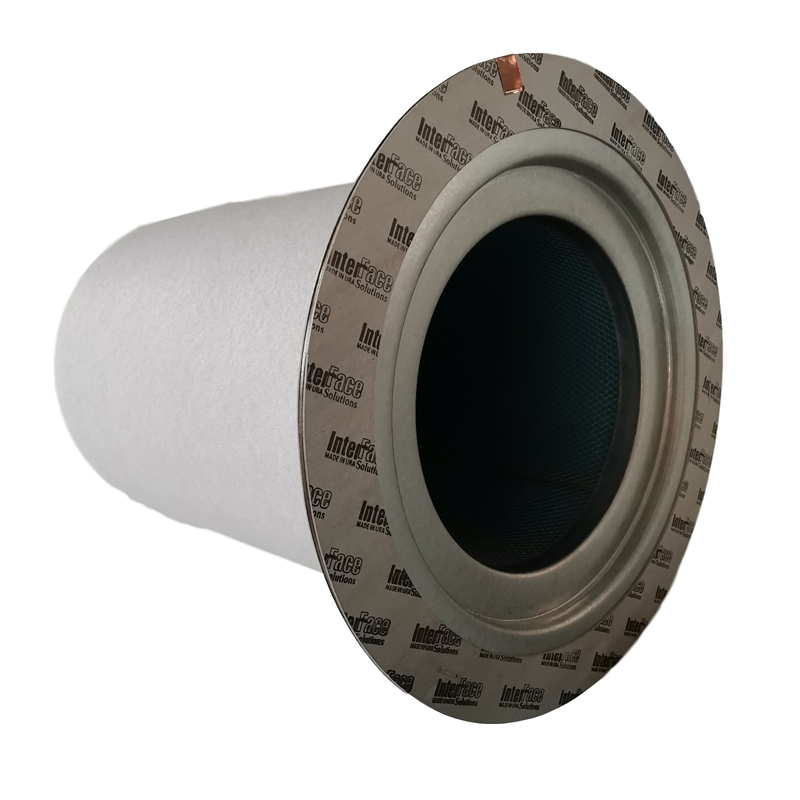

2. If there is no metal needle or copper sheet on the two gaskets configured with the oil and gas separation core, add them by yourself to ensure that the separation core is connected to the outside world and avoid combustion and explosion caused by electrostatic accumulation.

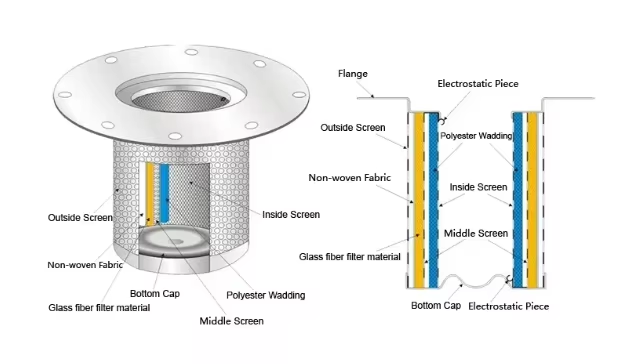

Product Structure