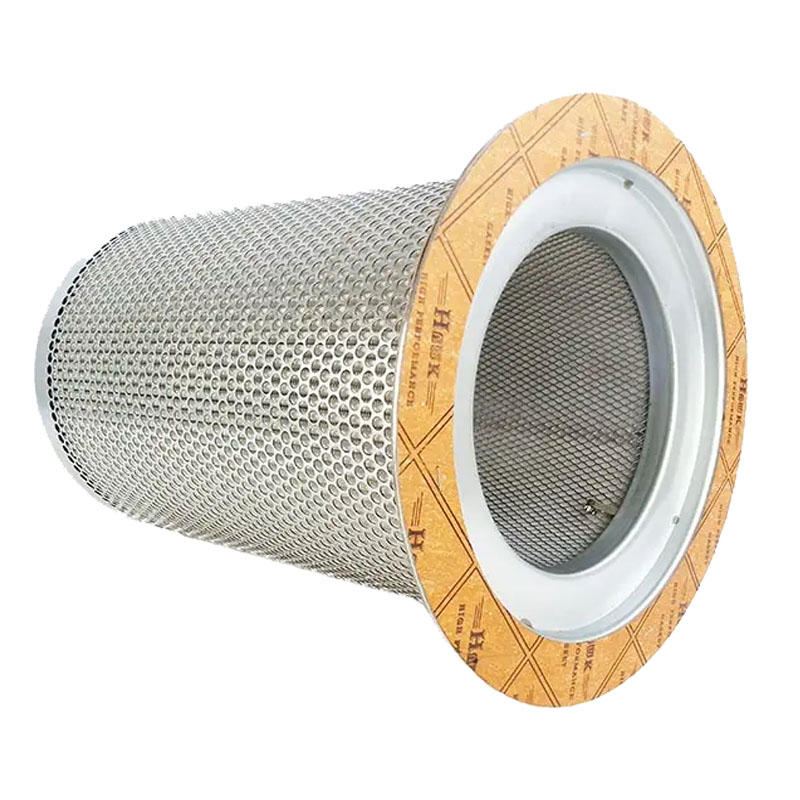

Wholesale 39751391 Oil Separator Filter Compressor Manufacturer Replace Ingersoll Rand Element

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

Screw air compressor is one of the power sources in the modern industrial field. It is one of the essential equipment in food, chemical, manufacturing and other fields. The timely maintenance of the air compressor is the basis for ensuring the normal, safe and effective operation of the equipment. The main function of the oil core of the screw air compressor is to separate lubricating oil and compressed gas. It is usually made of a porous filter material that is capable of intercepting oil droplets that are larger in diameter than their own aperture, allowing for effective separation of oil and gas. The design of the oil core includes the shape and size of the internal flow channel, which helps the small diameter oil droplets to coalesse into large diameter oil droplets under the action of inertial forces and are removed through the filtration process. To improve separation efficiency, high-performance materials such as ultrafine glass fibers, which are specifically designed for oil and gas separation, are often used. In addition, the oil core also helps to extend the service life of the compressed air system, ensuring that the compressed air does not contain excessive oil and water particles, thereby maintaining a high output quality and equipment life. During use, it is necessary to replace the oil core regularly, because the filtration performance gradually decreases over time. During operation, the replacement of the air filter is not timely, and impurities such as dust may enter the system and adhere to the surface of the oil filter. Low load operation, low exhaust temperature, lower than the pressure dew point, water blocking oil, this situation is easy to occur in high temperature and high humidity season. Users should follow the manufacturer's guidelines and schedule regular maintenance to ensure optimal performance.

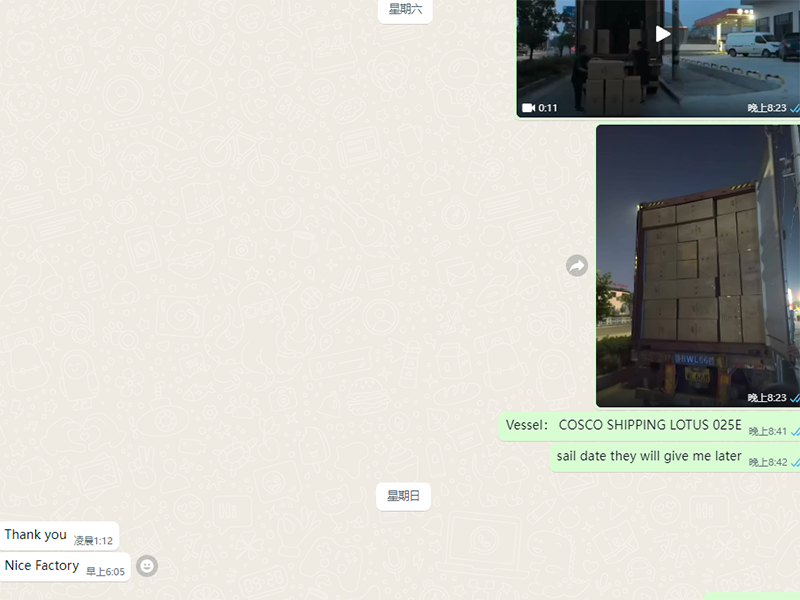

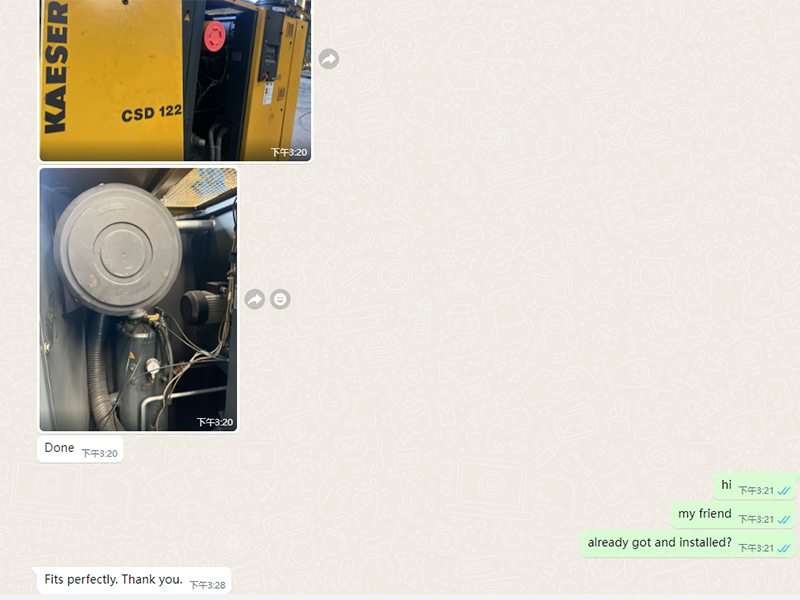

Customer Feedback

.jpg)

Buyer evaluation