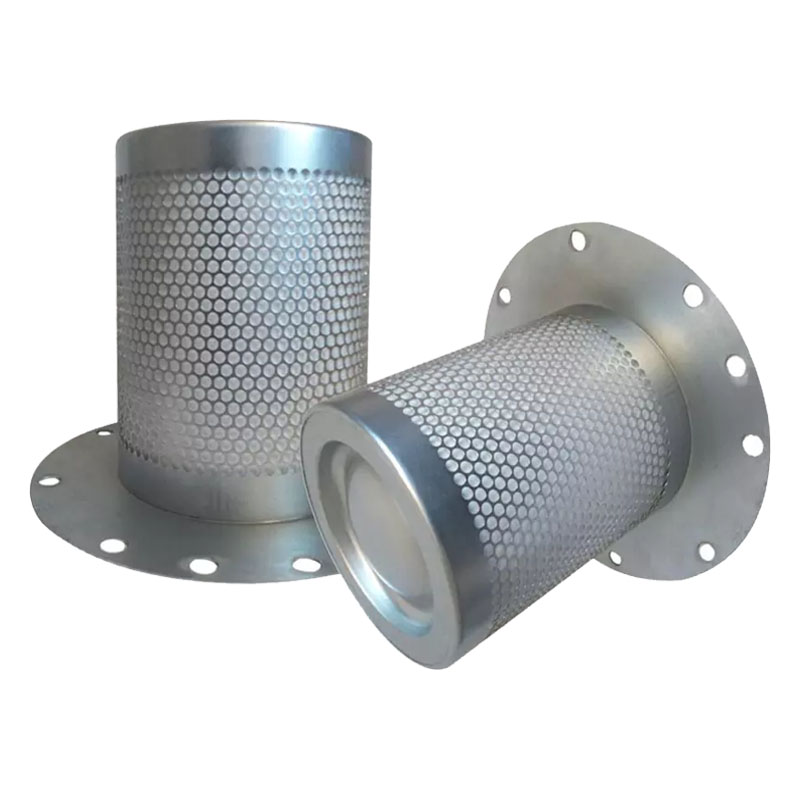

Wholesale 10533574 Oil Separator Filter Compressor Manufacturers

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

Screw air compressor filter element mainly includes the following types :

air inlet filter element : The main function of the air inlet filter element is to filter the dust, sand, foreign matter and other impurities in the air to ensure that the air entering the air compressor is clean, pure and pollution-free. At the same time, the air intake filter element can also reduce the noise and maintenance costs inside the air compressor, prevent impurities from blocking the intake system, so that the air compressor has a longer service life and more stable performance.

oil filter : The main function of the oil filter is to filter the oil dirt in the compressed air to ensure the purity and dryness of the compressed air. At the same time, the oil filter element can also protect the compressor lubricating oil system, extend the service life of the compressor, reduce the compressor maintenance costs.

oil and gas separation filter : oil and gas separation filter is used to separate the oil mist in the compressed air to ensure the dryness and purity of the compressed air. The filtration accuracy is usually 0.1μm, the filtration efficiency is as high as 99.99%, often using the United States imported filter material.

air filter : air filter is mainly used to filter the impurities in the air into the air compressor, the filtration accuracy is usually 5-10μm, the filtration efficiency is 98%, the service life can reach 2000 hours.

Different types of filter replacement cycle and maintenance methods:

air intake filter : every 1000 hours of operation needs to be cleaned, generally replaced every 3000 hours. Cleaning methods include opening the back cover, taking out the filter element, cleaning the inside of the filter shell with a damp cloth, and blowing the dirt in the filter element from inside out with 2-3bar compressed air.

oil filter : 500 hours of initial operation or every 4000 hours need to be replaced. During replacement, release the pressure in the pipe, remove the old filter element and washer, clean the sealing surface, install the new filter element, and check for leakage.

oil and gas separator core : when the display value of the pressure gauge on the oil and gas separator barrel is higher than the display pressure value of the liquid crystal plate by 1bar, it needs to be replaced. The replacement procedures include releasing pressure, removing pipes and gland, removing the separation core, cleaning the sealing surface, installing a new separation core, and replacing the gland and pipe.

Regular inspection and replacement of these filter elements can effectively extend the service life of the air compressor, reduce maintenance costs, and ensure the purity of the compressed air and the cleanliness of the lubrication system.

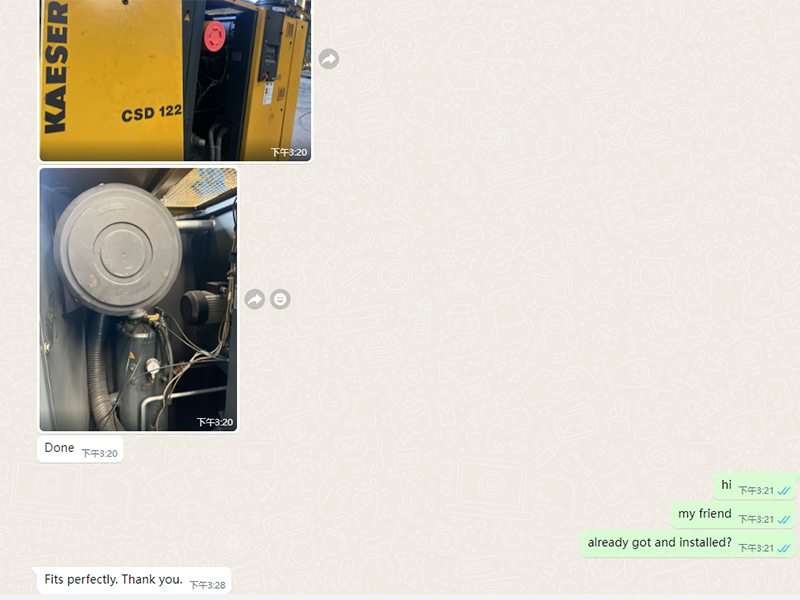

Buyer evaluation