The filter element of a screw air compressor is a key component to ensure the efficient operation of the equipment. It mainly undertakes the core functions of filtering impurities and separating oil and gas, directly affecting the performance stability and service life of the air compressor. Common filter elements include air filter elements, oil filter elements and oil-gas separation filter elements. The following is an introduction from three aspects: function, selection and maintenance.

1. Classification of Core functions

Installed at the air intake of the air compressor, it filters dust and particles in the inhaled air to prevent impurities from entering the main unit and causing wear. High-quality filter elements are made of multiple layers of high-precision filter paper or synthetic fibers, with a filtration accuracy of less than 5 microns, ensuring the cleanliness of compressed air.

It is used to filter out metal debris, carbon deposits and other contaminants in lubricating oil to prevent oil passage blockage or abnormal wear of components. Its interior is usually made of glass fiber or sintered metal materials, which can withstand high temperatures and high pressures, ensuring the cleanliness of the oil.

Oil and gas separation filter element

Located inside the oil-gas separator, it efficiently separates oil droplets in the compressed air through multiple layers of composite filter materials, reducing the oil content in the exhaust (which can be controlled below 3ppm), minimizing lubricating oil loss, and simultaneously improving air quality.

2. Selection and adaptation points

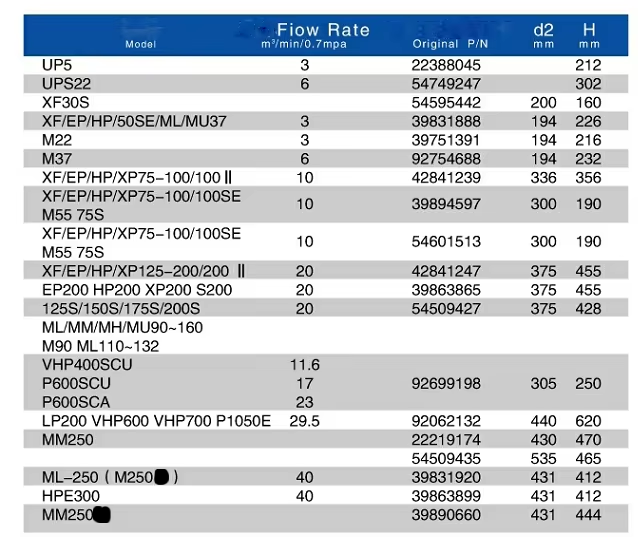

Matching equipment model : The appropriate specification should be selected based on the brand, power and working pressure of the air compressor to avoid a decrease in filtration efficiency due to size or flow rate mismatch.

Performance parameters : Focus on filtration accuracy (e.g., air filter element ≥99.5%), dust holding capacity and pressure resistance. In high-temperature environments, filter materials with a temperature resistance of > 120 ° C should be selected.

Certification standards : Give priority to products that have passed international certifications such as ISO 8573 (compressed air quality) and ISO 29463 (filtration efficiency) to ensure reliability.

3. Maintenance and replacement suggestions

Regular inspection : Dust on the surface of the air filter element should be cleaned every 500-2000 hours. The oil filter element and oil-gas separation filter element are recommended to be replaced every 2000-4000 hours (adjust according to working conditions).

Replacement signal : The filter element needs to be replaced immediately when the exhaust volume of the equipment decreases, the oil temperature rises or the differential pressure alarm (> 0.8bar) occurs.

Operating specification : Clean the filter cartridge housing when replacing to prevent impurities from falling into the system; Using original or equivalent quality filter elements, inferior products are prone to cause damage to the main unit.

Summary : Screw air compressor filter element is the “guardian” that ensures the high efficiency, energy saving and long service life of the equipment. Scientific selection and regular maintenance can not only reduce energy consumption and maintenance costs, but also avoid the risk of shutdown caused by filter element failure, providing crucial support for the stability of enterprise production.

Post time: Apr-17-2025