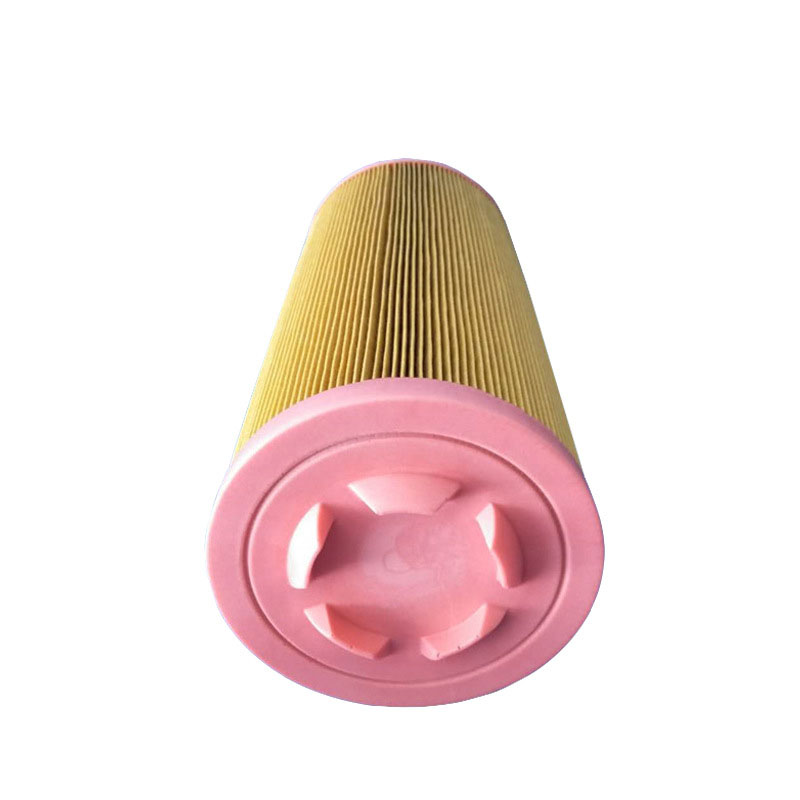

Manufacturers Supply C14200 30HP New Meshless Screw Air Compressor Parts Air Filter Cartridges 2914930200 9610512-N0450-M1 1622017100 2914930400

Product Description

The production of air compressor air filter is mainly divided into the following steps:

1. Select materials

Air filters use different materials, such as cotton, chemical fiber, polyester fiber, glass fiber, etc. Multiple layers can be combined to improve filtration efficiency. Among them, some high-quality air filters will also add adsorption materials such as activated carbon to absorb more harmful gases.

2. Cut and sew

According to the size and shape of the air filter, the filter material is cut using a cutter, and then the filter material is sewn, ensuring that each filter layer is woven in the correct way rather than pulled or stretched.

3.Seal

By making the end of the filter element, ensure that its suction enters an opening of the filter, and the outlet of the filter is tightly fitted to the outlet. It is also necessary to ensure that all stitches are firmly attached and that there are no loose threads.

4. Glue and bake dry

The filter material requires some bonding work before general assembly. This can be done after sewing, etc. Subsequently, the entire filter needs to be dried in a constant temperature oven to ensure optimal filter performance.

5. Quality check

Finally, all the produced air filters need to go through strict quality checks to ensure that they meet the standards and ensure safe use. Quality checks can include a variety of tests, such as air leakage tests, pressure resistance tests, and the color and consistency of the protective polymer housing.

The above is the production step of the air compressor air filter, each step requires professional operation and skills to ensure that the quality of the air filter produced is reliable, stable performance, and to meet the requirements of filtration efficiency.