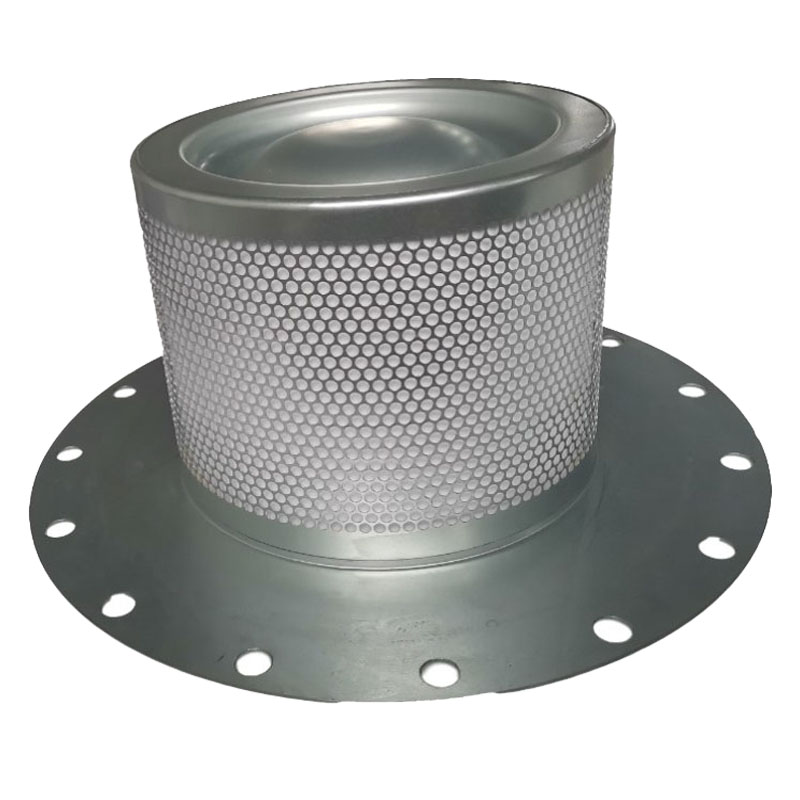

Wholesale Oil Separator Sullair Filter 250034-124 250034-130 250034-114 250034-862 250034-112 250034-085 250034-134 250034-116 250034-118 Replacement Air Compressor Spare Parts

Product Description

The oil and gas separator filter material is made of ultra-fine glass fiber composite filter material from American HV Company and American Lydall Company. The misty oil and gas mixture in the compressed air can be completely filtered when passing through the oil separator core. The use of sophisticated seam welding, spot welding processes and the developed two-component adhesive ensures that the oil and gas separation filter element has high mechanical strength and can work normally at a high temperature of 120°C.

Filtration accuracy is 0.1 um,Compressed air below 3ppm,Filtration efficiency 99.999%,The service life can reach 3500-5200h,Initial differential pressure: ≤0.02Mpa,The filter material is made of glass fiber.

The oil and gas separator is a key component responsible for removing oil particles before compressed air is released into the system. It works on the coalescence principle, which separates the oil droplets from the air stream. The oil separation filter consists of multiple layers of dedicated media that facilitate the separation process.

The first layer of the oil and gas separation filter is usually the pre-filter, which traps larger oil droplets and prevents them from entering the main filter. The pre-filter extends the service life and efficiency of the main filter, allowing it to operate optimally. The main filter is usually a coalescing filter element, which is the core of the oil and gas separator.

The coalescing filter element consists of a network of tiny fibers that create a zigzag path for compressed air. As air flows through these fibers, oil droplets gradually accumulate and merge to form larger droplets. These larger droplets then settle down due to gravity and eventually drain into the separator's collecting tank.

The efficiency of oil and gas separation filters depends on a number of factors, such as the design of the filter element, the filter medium used, and the flow rate of compressed air. The design of the filter element ensures that the air passes through the maximum surface area, thus maximizing the interaction between the oil droplets and the filter medium.

Maintenance of the oil and gas separation filter is essential to ensure its proper operation. The filter element must be checked and replaced regularly to prevent clogging and pressure drop.

Product Description