China Wholesale 10525274 Oil Separator Filter Element for Air Compressor

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

Analysis of oil function of screw air compressor:

1.Lubrication

The core component of the screw air compressor, the screw, compresses the air through high-speed rotation, which requires the formation of an oil film between the screw and the housing to withstand the friction and wear caused by high-speed operation. Therefore, the oil content of the screw air compressor is mainly to lubricate the contact surface between the screw and the housing, reduce wear, prevent premature damage to parts, and extend the service life of the air compressor.

2.Sealing effect

The oil content of the screw air compressor can also play a sealing role in the process of compressed air. A small amount of oil is injected into the gap between the screws, and through oil lubrication and adhesion, it can play a role in sealing and reducing leakage. This is essential for applications that require high quality compressed air, such as food and beverage industries.

3.Cooling effect

In the process of compressed air, the screw air compressor will generate heat because of friction, and the temperature will rise rapidly, at which time the oil will provide cooling for the screw and the housing. The oil can take away the heat generated by the flow, and cool the air compressor system to maintain the normal working temperature of the equipment.

When selecting and maintaining the oil content of the screw air compressor, the following points need to be noted:

1.Select the appropriate oil grade and viscosity, generally in accordance with the compressor manufacturer's recommended operating manual.

2.Replace the oil regularly, and do the maintenance and replacement of the oil.

3.Pay attention to safety in the maintenance process, turn off the power, and follow the correct operation process.

4.Pay attention to the oil level and oil quality of the oil during use, and troubleshoot in time to avoid affecting the normal operation of the equipment.

In short, the oil of the screw air compressor plays three important roles in lubrication, sealing and cooling to ensure the normal operation of the screw air compressor and extend the life of the equipment. Therefore, when selecting and using oil, it is necessary to understand its role and characteristics, and perform maintenance and maintenance in accordance with the correct method.

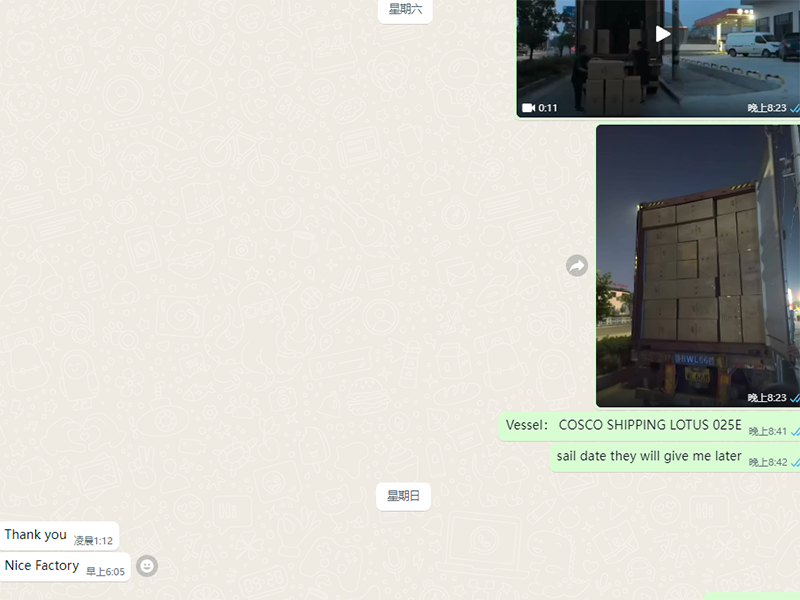

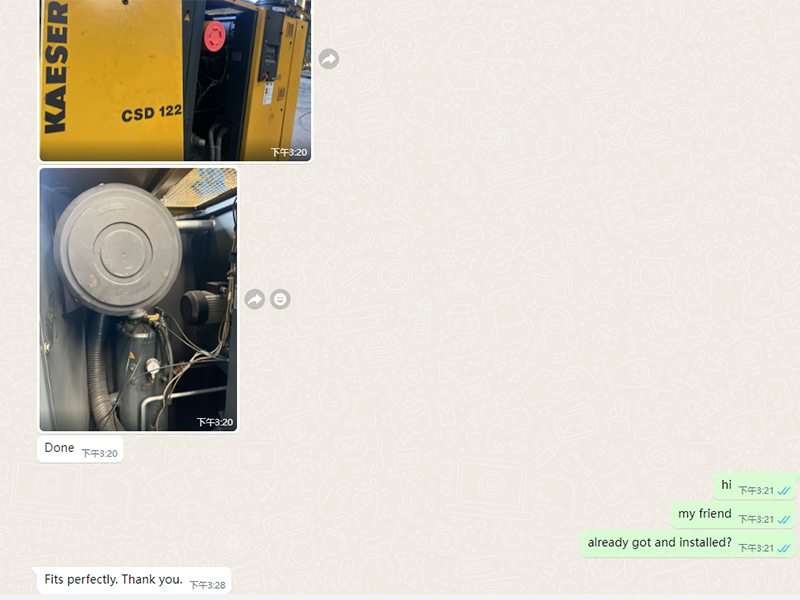

Customer Feedback

.jpg)

Buyer evaluation