China Compressor Oil Separator Atlas Copco 2901007000 Replace for Air Compressor

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

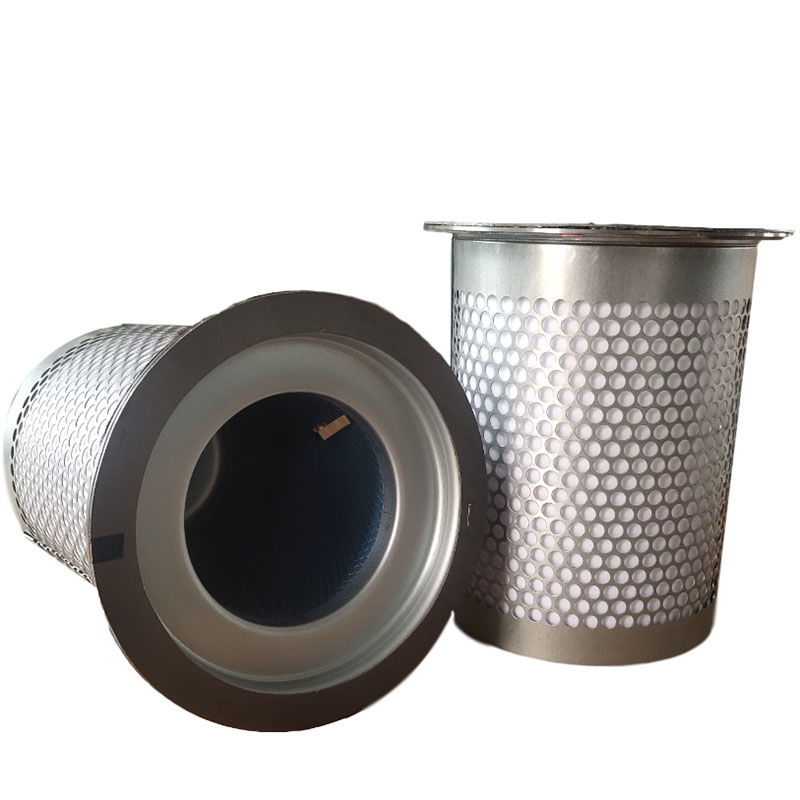

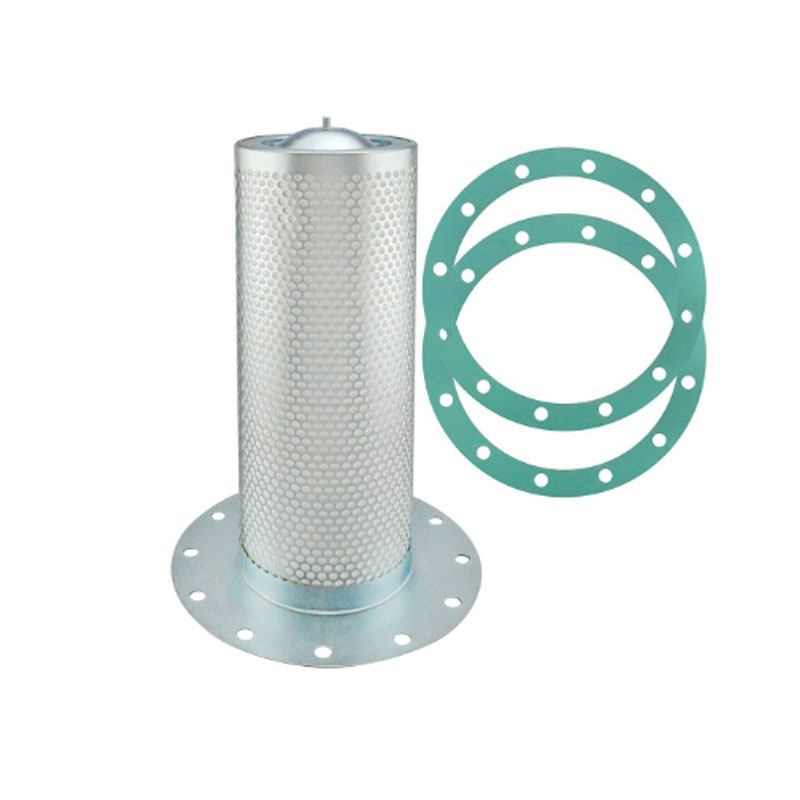

The Jinyu Company Oil-Gas Separation Filter Element (Part No.2901007000) is a high-performance component engineered for screw air compressors, designed to optimize the separation of compressed air and lubricating oil while ensuring operational efficiency and longevity. Unlike generic filters, this model integrates advanced material science and precision engineering to address common industry pain points such as premature clogging, pressure drop instability, and environmental contamination.

Core Design and Material Innovation

Constructed with a proprietary multi-layer composite media, the filter employs a hybrid structure combining borosilicate microglass fibers and a hydrophobic nanocoating. This unique combination achieves a filtration efficiency of ≥99.97% for oil aerosols as small as 0.1 microns, far exceeding the ISO 8573-1 Class 1 standard. The media is reinforced with a corrugated steel mesh core, providing structural integrity under fluctuating pressures up to 13 bar. Notably, the filter incorporates an anti-static treatment to mitigate fire risks in oxygen-rich environments—a feature rarely seen in conventional models.

Performance Enhancements

The 2901007000 filter is optimized for low oil carryover, with a residual oil content of ≤3 ppm, reducing downstream contamination in sensitive applications like food processing. Its asymmetrical pleat design increases surface area by 40% compared to standard filters, extending service intervals to 6,000–8,000 hours under typical conditions. A patented anti-drainback valve prevents oil migration during shutdowns, preserving lubrication systems and minimizing cold-start wear.

Compatibility and Adaptability

While designed for Jinyu’s GX-series compressors, the filter’s universal flange interface allows compatibility with major brands such as Atlas Copco, Ingersoll Rand, and Sullair. It operates effectively in extreme environments, maintaining performance between -25°C and 120°C, making it suitable for Arctic drilling rigs or tropical industrial plants. The housing features laser-etched QR codes for traceability and real-time lifecycle monitoring via IoT-enabled compressor systems.

Sustainability Focus

Aligned with circular economy principles, the filter uses 30% recycled stainless steel in its casing and is 95% recyclable. A biodegradable synthetic fiber layer replaces traditional plastic components, reducing landfill waste. Independent testing by TÜV Rheinland confirms a 22% lower carbon footprint compared to industry averages.

Customer Feedback

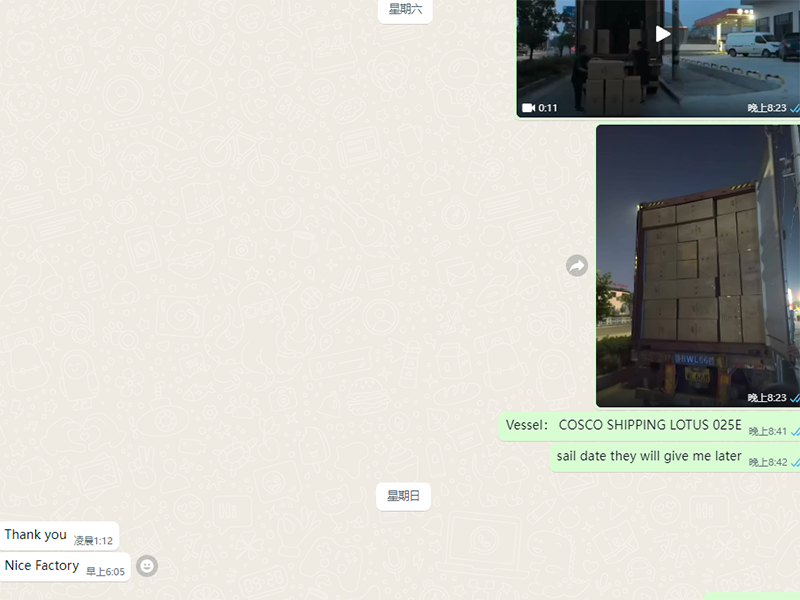

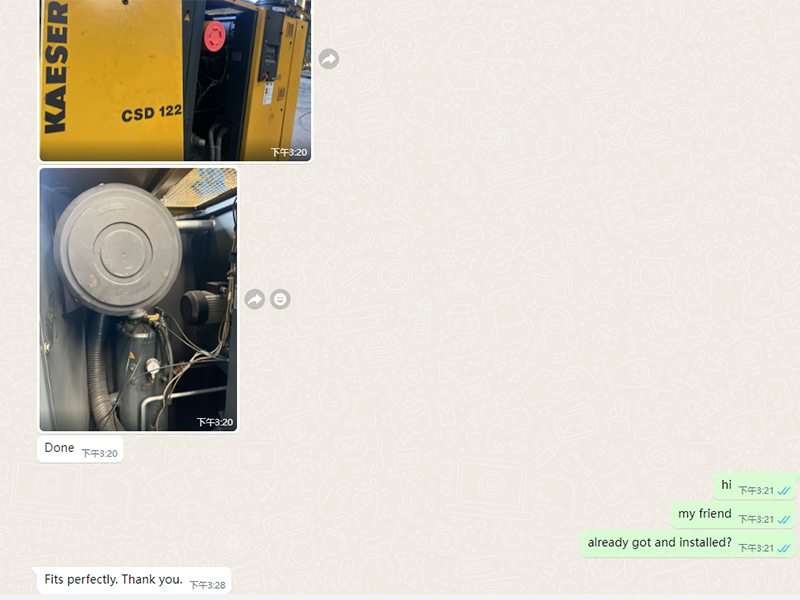

.jpg)

Buyer evaluation