China Air Compressor Oil Separator 575000101 Filter Separator Kompresor Screw

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

Precautions when installing the oil and gas separator filter element:

1. Apply a small amount of lubricating oil on the surface of the seal when installing the oil and gas separator filter element.

2. During installation, the filter element of the rotary oil and gas separator only needs to be tightened clockwise by hand.

3. When installing the built-in oil and gas separator filter element, a conductive plate or graphite gasket must be installed on the flange gasket of the oil and gas separator filter element.

4. When installing the built-in oil and gas separator filter element, pay attention to whether the return pipe extends to the center bottom of the oil and gas separator filter element between 2-3mm.

5. When unloading the filter element of the oil and gas separator, pay attention to whether there is still excess pressure inside.

6. The compressed air containing oil cannot be directly injected into the filter element of the oil and gas separator.

Screw air compressor oil and gas separator replacement method:

Replacing the oil and gas separator is an essential operation during the maintenance of the screw air compressor. The service life of the normal oil and gas separator is about 3000h, and it must be replaced with a new one when it expires or the pressure difference exceeds 0.12Mpa. The method of replacement of different types of oil and gas separators is also different. Common models include built-in models and external models, and the specific replacement methods are as follows:

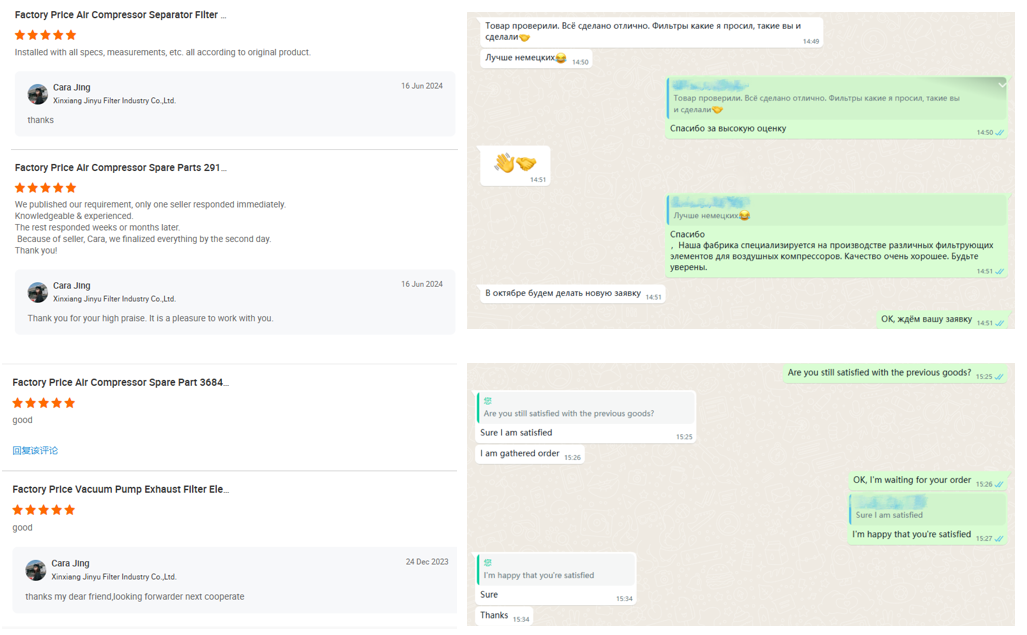

Built-in model:

1. Stop the screw air compressor, close the air compressor outlet, open the water drain valve, and confirm that there is no pressure in the system.

2. Disassemble the pipeline above the oil and gas barrel, and remove the pipeline from the pressure maintenance valve outlet to the cooler.

3. Remove the air compressor return oil pipe.

4. Remove the fixing bolts on the oil and gas barrel and remove the cover of the oil and gas barrel.

5. Remove the oil and gas separator and replace it with a new oil and gas separator.

6. Install it in the order it is removed.

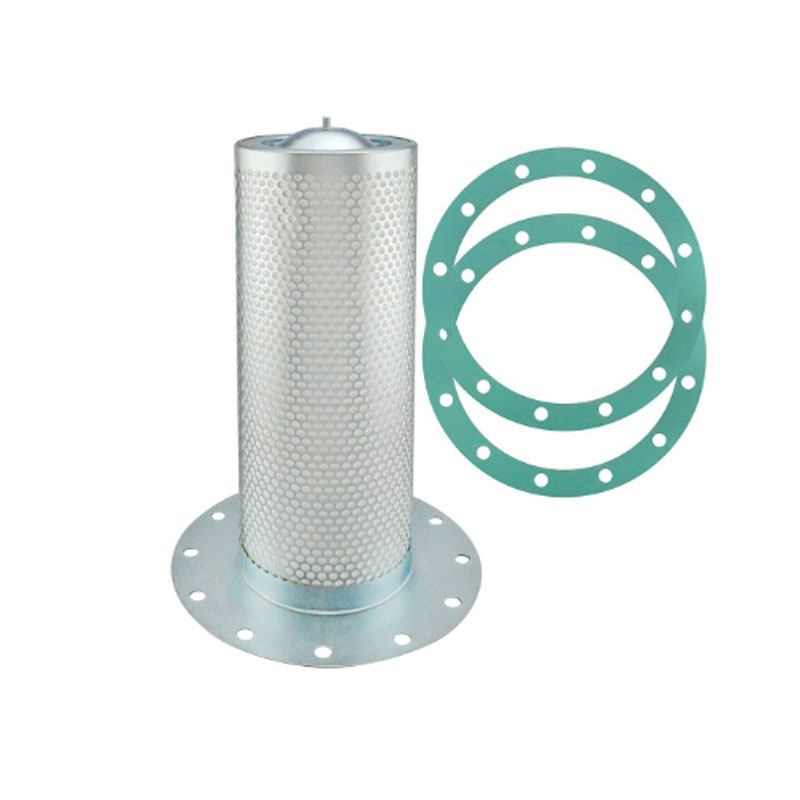

External model:

Shut down the air compressor, close the air pressure outlet, open the water drain valve, and confirm that there is no pressure in the system, remove the old oil and gas separator and replace the new oil and gas separator.

Buyer evaluation