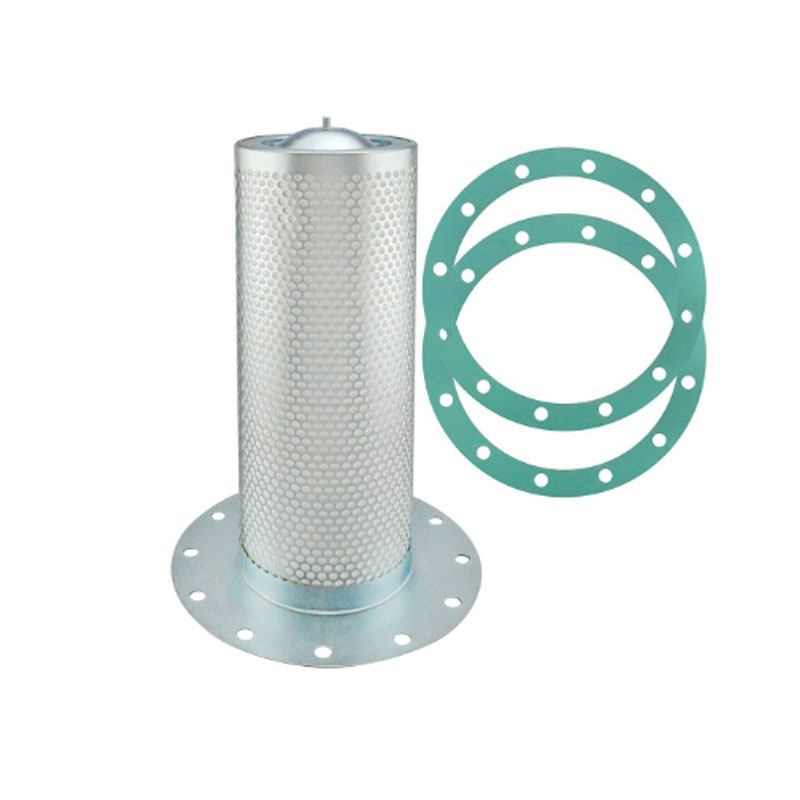

Wholesale 2914505000 Air Compressor Coolant Oil Filter for Atlas Copco Filter Replace

Product Description

Tips:Because there are more 100,000 types of air compressor filter elements, there may be no way to show one by one on the website, please email or phone us if you need it.

The function of the oil filter is to remove metal particle impurities in the oil, and the filtration accuracy is between 5um and 10um, which has a protective effect on the bearing and the rotor.

Determine whether the oil filter needs to be replaced by the differential pressure indicator. If the differential pressure indicator is on, it indicates that the oil filter is blocked and needs to be replaced. If it is not replaced, it may lead to insufficient oil intake, resulting in high-temperature exhaust gas trip and affecting the service life of the bearing.

The service life of the oil filter is generally determined by two factors:

1.the number of impurities. When the oil filter cannot absorb impurities, it can no longer be used;

2.machine temperature and anti-carbonization capacity of filter paper. Under high temperature conditions, the machine will greatly accelerate the carbonization of filter paper, shorten the effective use time of filter paper, and reduce the service life of oil filter; Under normal circumstances, the service life of good quality oil filters is about 2000-2500 hours, and the service life of poor quality oil filters will be shorter.

In addition, many people may think that the higher the accuracy of the oil filter, the better the filtration effect, but they are afraid of blockage. In fact, research shows that this is actually a misunderstanding, the filtration accuracy of the oil filter and the filtration effect is a certain relationship, but the real decisive role is the adsorption capacity of the filter paper, the stronger the adsorption capacity, the better the filtration effect. The reason for the good filtration effect of fiber filter paper is because of the large dust capacity, strong adsorption capacity, and strong carbonization resistance, but the price is more expensive, so the number of people is relatively small.